Radshape Sheet Metal plans to take on additional staff after new funding

Radshape Sheet Metal plans to take on additional staff after new fundingA precision sheet metal manufacturer has invested in new machinery after securing new finance.

Radshape Sheet Metal, based in Birmingham, has received a £500,000 funding package from a major bank which has lead to an expansion of its existing production line. The company are a leading manufacturer for a range of industries, including automotive, electrical and motorsport sectors.

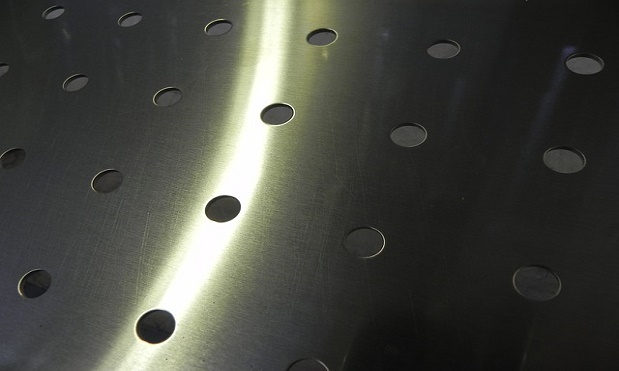

The firm has been a leading supplier for Rolls Royce and Bentley since its establishment in 1967 and specialises in developing both single prototype components and full assembles, such as petrol tanks and speaker grills.

The investment will enable the company business grow its product line and expand into new sectors, including the aerospace and rail industries. Lloyds Banking have supplied the funding which has also enabled the company to purchase a new Amada laser cutting machine.

Radshape Sheet Metal currently employs 70 people and has an annual turnover of around £4m, with plans to take on additional staff to support its growth ambitions.

The Managing Director of Radshape Sheet Metal, Keith Chadwick, said: “With over 40 years of experience in the manufacture of precision sheet metal parts, we take great pride in the high quality components and projects we deliver for our national customer base.

“In line with our plans for business growth in the next three years, it was vital for us to invest in this new equipment, which has allowed us to increase our production capabilities considerably in what is a competitive industry.

Claire Carr, Client Manager at Lloyds Bank Commercial Finance, added: “Radshape’s industry credibility in this highly skilled area of manufacturing is a real catalyst in fuelling the business’ ambitious plans for growth, and this latest acquisition of new machinery is a really important step, allowing it to further enhance its production capabilities.